Notifications

Hi Rudolf,

I think you know that. But I'll write it anyway. You can reduce copper oxidation, by enamelling a copper piece on both sides at the same time. There are some methods to do that. 1) Dip the whole piece in liquid enamel, let it dry and fire it. Lead Free liquid enamel you get in different colors by Thompson enamel. But you can make it also by yourself. Make a mix of a bit finer powdered Enamel + water + a bit holding-agent and about 1-2 % carbamide. The carbamide holds the enamel a bit in suspense. Before using, stir the liquid enamel. But be careful not to produce bubbles in the mix. Dry and fire it. By both methods you get only a bit copper oxidation at the rims of the piece.

The other possibility is sieving a thin layer of enamel on both sides of the work piece at the same time. Atomize onto one side of the ws a bit holding agent. Sieve on a thin layer of enamel, spray again, but so, that the enamel layer is only moisturized but not wet. Sieve on a new layer of enamel. This procedure can you repeat 2-3 times. At last spray again a thin film of holding agent, so that the enamel is well imbued. Let the enamel layers dry very well.

Turn up the work piece and make the same procedure on the rear side. After drying the ws well, put it onto a trivet and fire it.

As holding agent i use a mix of wallpaper glue and distilled water. Make an a bit thicker solution of the glue and give 10-20 drops of the stock solution into 100 ml distilled water. I use as a spray gun a flower-spray gun.

As holding agent i use a mix of wallpaper glue and distilled water. Make an a bit thicker solution of the glue and give 10-20 drops of the stock solution into 100 ml distilled water. I use as a spray gun a flower-spray gun.

Instead of copper wire for cloisonné I use a copper alloy wire 15/85. That means 15 % Zinc and 85 % copper is in the alloy. This alloy oxidized during all following firings only a bit, much more less than copper. The other advantage is, that the very thin oxidized film don't jump off during all following production steps. After grinding and firing the cloisonné, the wire get back its golden gloss and this gloss is stable for a long time, much, much longer than the gloss of copper wire.

Edmund willkommen :-)

richte ich für Sie wie zu :-)))))))))))

Wir haben die gleichen Gedanken :-))))))))

Gesundheit? Urlaub bald :-)

Leszek Kralka grüßen

ps ich danke Ihnen für Ihre Wertschätzung Schild Fregatte.

Thank you Edmund

Yes I know this technique, but the thing is I want etched design that will be enamelled and the copper will be then gold or silver plated. I can use sandpaper to remove the oxides and polish the coppper but that is lot of time and I am trying to avoid this. Is there any inexpensive metal that can be electroetched and doesn´t form oxides like copper?

Rudolf

Dear Rudolf,

Tombak 5/95 or 10/90 (% Zinc / Copper%) is somewhat more resistant to oxidation, but not so much that you really saves time. Moreover Tombak has the disadvantage that it can withstand only 2-5 firings. If an enamel-work more often fired on Tombak, there is the risk that the enamel peeling off.

There are two simple ways to save significant time during grinding.

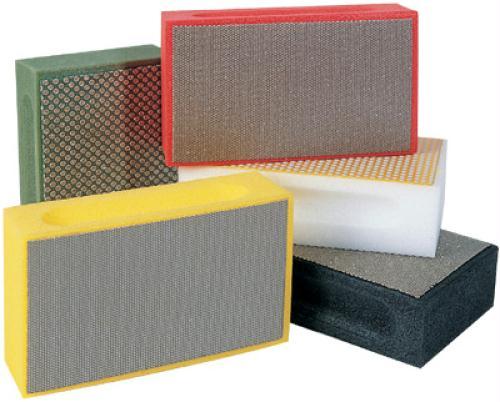

1.) Use instead of Carborundum abrasive diamond-abrasive-sponges. This diamond tools works much more effectively. I estimate, that you can save, when grinding with hand-diamond grinding tools, at minimum 25% - 30% working-time and more.

1.) Use instead of Carborundum abrasive diamond-abrasive-sponges. This diamond tools works much more effectively. I estimate, that you can save, when grinding with hand-diamond grinding tools, at minimum 25% - 30% working-time and more.

2.) Even more time you can save with an electric wet grinding machine. Commercial machines are very expensive. That's why I built from a cordless screwdriver a machine by myself. The most expensive part of this machine are the diamond abrasive belts. The machine is easy to recreate. I have the plan ever published here in the forum. Unfortunately I cannot find again it here in the forum. If you are interested, please write an email to massow@emailkunst.de. I am sending you a copy then.

2.) Even more time you can save with an electric wet grinding machine. Commercial machines are very expensive. That's why I built from a cordless screwdriver a machine by myself. The most expensive part of this machine are the diamond abrasive belts. The machine is easy to recreate. I have the plan ever published here in the forum. Unfortunately I cannot find again it here in the forum. If you are interested, please write an email to massow@emailkunst.de. I am sending you a copy then.

I grind and polish with this machine my about 25 x 25 cm large Cloisonné enamel plates in less than one hour to a silk like gloss .

Edmund

Edmund Thank you for the information