Notifications

I am new to enameling, but I would like to make my own fine silver rectangular wire for enameling, in various heights and widths with a rolling mill (and I don’t want to use drawnplates...I don’t have the hand strength because of arthritis).

I haven't been able to fine fine silver rectangular wire, other than thin bezel wire.

My vision is to be able to shape the rectangular wire, fuse it down to a fine silver base plate, and then treat as champleve, as well as use it as elements within the enamel field

What is the best way to do this? I have had the suggestion to get a mill with rollers that mills rectangular wire, but I was wondering if the rectangular wire turns out as wonky as the round wire that is mill rolled which must be run through round drawplates. Also, a rolling mill would seem to confine you to a certain ratio of width/height.

Could anyone share how they make their own?

Many thanks for any information!

Hi Elizabeth,

I would speak with Rio Grande who carries rolling mills and find out what the capabilities are with rolling mills and the issues you might face with irregularities and gauges of metal.

Have you called Hoover & Strong or Hauser and Miller for rectangular wire?

To prevent your wire from going wonky you should apply some tension on it while rolling (and anneal it beforehand). And go gradually from thicker to thinner. And make sure your rollers are parallel. And make sure your wire enters always with the same angle. The best way to achieve this is to apply some tension downwards. This way your wire will be naturally forced into the gutter if you use patterned rollers. And if you use flat rollers you can lean your hand against the mill support (table/whatever you fixed it to) and it'll be more stable. You should anneal the wire after rolling as well.

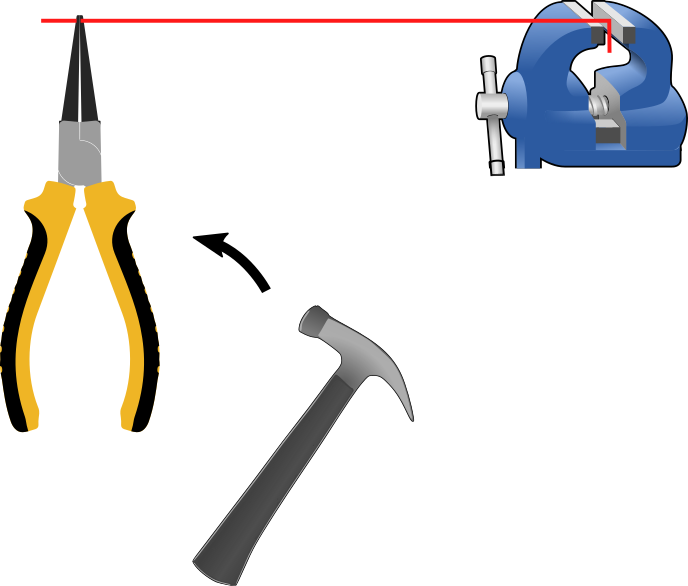

If the outcome is still not straight enough you can straighten it by pinching one end in a vise (rolling mill may pinch hard enough too, but never tried it that way), grab the other end with pliers, extend the wire, then hit gently against the pliers with a hammer, like this:

Never seen rollers for rectangular profiles. Square ones are quite common though.