Notifications

Hello All!

I am very new to enameling and am trying to enamel on silver charms. This first charm I did (a pineapple) on sterling silver worked great- I had no problems and became very optimistic about the rest of my project! However, every charm I've tried to enamel afterwards has cracked. The charms are cast and in the round, and the enamel is going on the outer surface, so no cloisonne like the pineapple had. I had a few cast in sterling but am wondering if I will have better luck if I cast them in fine silver?

I am thinking that my main problem is probably the enamel being too thick - but, I don't see how to get the enamel even without making it thick. I've tried sifting and wet packing. Enamel is all opaque, Thompson's enamel for copper, gold, and silver.

Any help would be so appreciated!!! Also- does anyone know of any good books on encrusted enameling or email en ronde-bosse? Thanks in advance! - Kallie Compton

Hi Kallie,

I would suggest counter enameling on the back with a hard enamel - Your castings are probably thin in gauge so there is no support when cooling - Think of an oreo cookie - enamel on the top and back - metal in the middle - as the piece cools from the kiln both enamel and metal are moving .

You may also face a bit of a color changing problem if you use transparents on sterling & fine silver, as the salts disrupt the color in light transparents - I cast in fine silver but I am using transparents over a flux - I did find that one of my pansy pieces cracked even tho the gauge was fairly thick. - so I countered with Thompsons Blue Black opaque - which I like because it can take high firing without trouble - I had no problem with cracking after that - but you can try other colors as long as it is a hard enamel.

You can counter all those cracked pieces and put them back in the kiln and refire - the cracks will seal up - but make sure you clean them with a glass brush and water first, dry well, counter enamel and fire up!

Also you don't have to put a thick layer on the first go round - you can apply one thin layer - fire - cool and reapply a second thin coat - and fire - make sure you have counter enamel. If you use reds, apply them last with other colors as they burn out quickly and don't overfire.

Good luck,

Trish

Hello Trish! Thank you so much for your detailed reply.

I am not counter enameling because these pieces are in the round, on thick 3D surfaces. For example- One is an orange. If you took a real orange and shrunk it to 15mm tall, thats what my casting looks like. I need to cover the whole surface with orange enamel. All my enamels are opaque. Is there a good resource for troubleshooting problems like this, or do you know of anyone specifically who has had success enameling on 3d castings? I am at a loss

Hi Kallie,

After conferring with Tom Ellis from Thompson's enamel, I believe we have the answers to your problems. Altho they may not be positive for you - and he will be sending me a fact sheet with a more complete analysis of enameling on castings. Here are some quick tips -

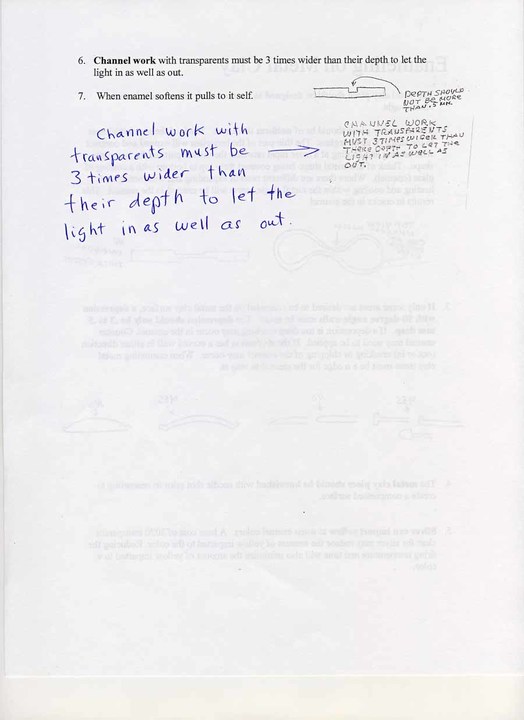

1. Castings should have a controlled design - Not all shapes for castings work well for enamel. The enamel needs to have a starting and stopping place like a support wall.

2. The depressions in the metal where the enamel is to be placed must be of uniform thickness and at a depth of .3 to .5 deep.

3. Fine Silver is better for enamel castings - You should tumble the castings before enameling in a Magnetic Needle Shot tumbler which seals the porous metal. (something I also did not know)

Probably your pineapple came out well because of the cloisonné cells which create a wall for the enamel.

I will forward the fact sheet once he emails it to me.

Regards,

Trish

From Tom Ellis - Enameling rules for Metal Clay and also Castings-

Wow thank you so much this is very helpful!!!

HI Kallie,

Trish asked me to offer my help here. Sorry I didn't see her message until today.

These tips look great from Tom Ellis.

I apply liquid enamel to 3D steel shapes using spray applications, although I do apply a ground coat layer to the steel first, so I don't know if this approach will work directly on sterling silver.

If you want to try it, i teach this method.

Let me know if your problem has been solved, or if you still need help with it.

Thanks, Alisa Looney