Notifications

Bending prongs over an enamelled plate.

Maybe these tips will help you further.

1) Make the prongs of soft fine silver. Alloyed silver can be too hard.

2) Flat prongs of about 0.3-0,4 mm thick sheet metal are easier to bend than prongs from round wire.

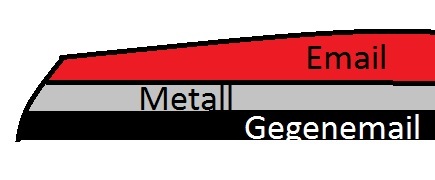

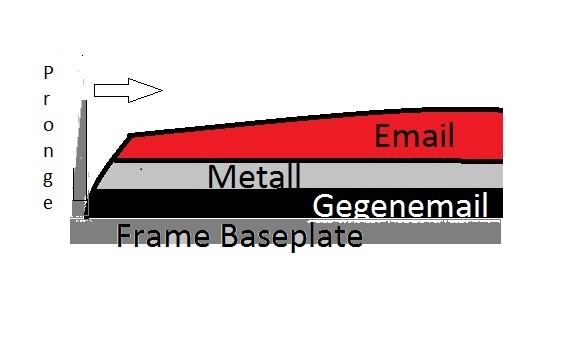

3) The edge of your enamel plate should be slightly rounded. (Picture above, left side) This reduces the pressure on the enamel edge.

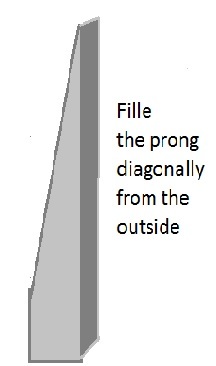

If you the pronge from the outside diagonally from bottom to top file down, you can bend it more easily

If you the pronge from the outside diagonally from bottom to top file down, you can bend it more easily

And here are a few links to Ganoksin, where you can find further descriptions of how to make Bezel for enamel plates

https://www.ganoksin.com/article/how-to-make-a-bezel/

https://www.ganoksin.com/article/making-metal-brooch-frame/

https://www.ganoksin.com/article/making-metal-brooch-frame/

Edmund

What is ¨gegenemail ¨?

Hi Sharon,

Gegenemail = Counterenamel, that means enamel at the back-side of the enamelled sheet

Did the above file help you a bit??

Edmund

Yes, except I don't do any enamel work that has straight sides. Mine are all sawed shapes like leaves or abstract shapes. Also I use wire and complex sawed shapes together that are enameled. Somewhat different to put into a backing bazel.

Thanks for your help.

Emailplate setting with prong

.Maybe you work similar. But possibly this description will help other prospects.

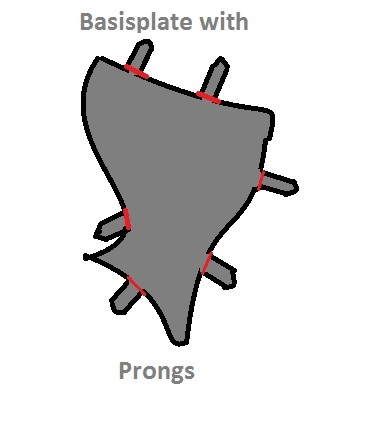

Saw out the base plate from approximately 0,4 - 0.5 mm thick sheet metal according to the contour of the enamel plate. During sawing, allow the prongs to stand at strategic points. Very close to the contour of the enamel plate, file a 0,2 mm deep triangele into the prongs. (In the sketch the red lines). Place the finished enamel plate on the base plate and bend the prongs upright. Shorten the prongs so that they are about 2-3 mm longer than the embedded enamel plate is high. If necessary, file the prongs at the topb a little bit round and slightly wedge-shaped on the outside from bottom to top. This makes it easier to push the prongs over the enamel plate.

As a bottom plate, I take either about 0.4 -0.5 mm thick fine silver or soft annealed sterling silver plate.

Hook and needle-rest will of course be soldered before setting the enamel plate fianal.

Two examples for prong setting

Edmund

Thank you again. I have tried all of these methods with varying degrees of success.

I think what I am not explaining well is my main problem is how to bend the prongs over without

cracking the enamel.

I have make them thin, annealed them, and filed a grove but still have not found a satisfactory way to curl/bend

the prongs so they fit tightly enough to not move in the setting.

Maybe a tiny piece of something to act as a cushion between the under prong and the enamel.....

Thank you for your help.

Sharron

I think it is quite important for this forum that not only compliments are exchanged but also advice is given to solve technical problems. Thank you Edmund!

Google Übersetzer

Dear Edmund, I am quite certain that many members of this forum would want to profit of your vast knowledge and experience about enameling. So I fully encourage you to dig in the depth of your computer to share your advice with us who are all interested in this topic.

The exhibition in a gallery in the old town of Zürich was very successful. Many visitors came, there were many compliments and congratulations. Nine enamel pictures and three clocks have been sold during the exhibition. My daughter sold even more of her works. I add a couple of photos showing the two rooms of the exhibition, one for enamels and the other one for water colors of my daughter. Thank you for your interest in our work!

Kind regards

Gabor

Dear Gabor,

Thank you for the beautiful pictures of your exhibition in Zurich. This is really a nice gallery and the presentation is really great. And I am very pleased with your success.

Edmund

Thank you Edmund for your very kind comment!

I use 18 gauge sterling silver wire prong settings on some of my enameled cabochons. I am very careful to bend them over the domed surface using a burnisher. I have two short tutorials on my blog. One is for a convex domed cabochon. The other is for a concave cabochon. It isn't as detailed. What it leaves out is that I used a square file to create a little V shaped groove in each of the wires where they touched the enameled surface. That gave them room to bend cleanly without cracking the enamel. I know I learned that from some book out there for metalsmiths and just applied it to my work in enamel. Just be patient when bending your prongs over. Do one first and then do the one on the opposite side (just like you would if setting a stone). Repeat with the remaining prongs. I hope this helps.