Notifications

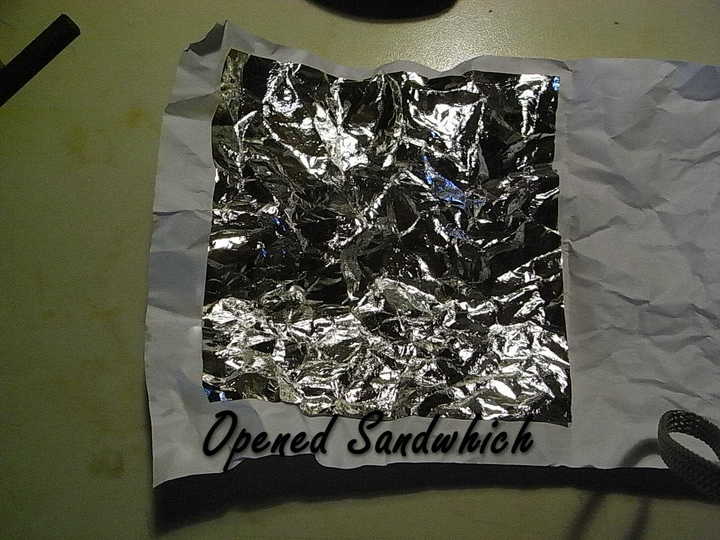

Place the foil between 2 pieces of thin paper and form the sandwhich into a ball. Fold the ball apart and smooth the foil slightly. You get a beautiful curled silver foil

WOW! Thank you Edmund - I was thinking along those lines but couldn't figure out how to unball the fine foil-

Never too old to learn something new.

Thanks,

Trish

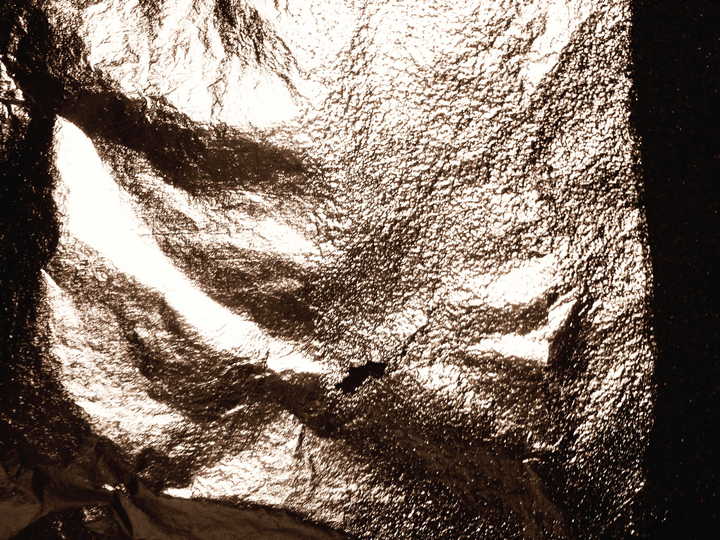

Silverfoil crinkle

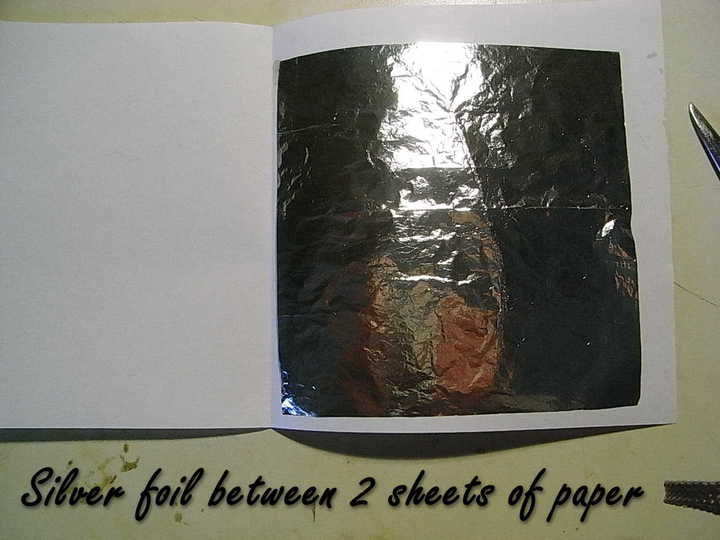

1) Lay the foil between 2 sheets of paper so that a paper-foil-paper sandwich is created.

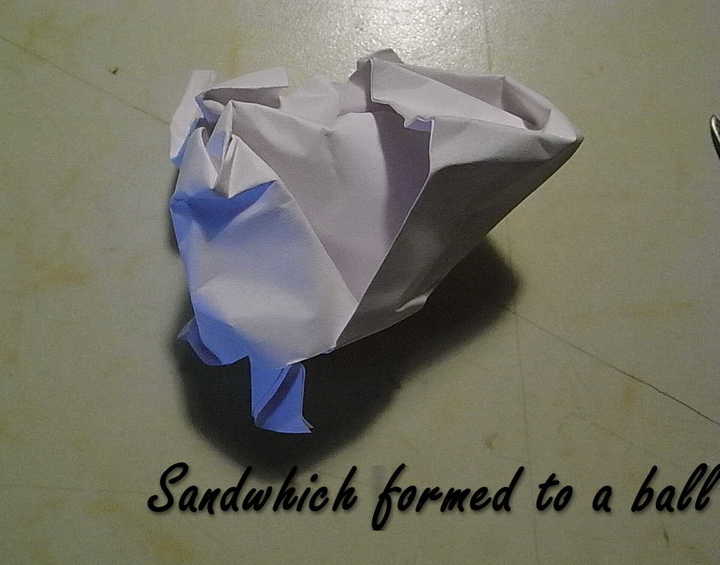

2) Squeeze the foil into a ball, the tighter the ball is compressed, the more the foil is crumpled.

4) Remove the foil. To get the foil flat, swipe directly over the foil with a soft kitchen paper towel without pressure.

5) Moisten the pre-enameled work-piece with some water or adhesive.

6) Apply the foil to the work-piece and press the foil well with a kitchen paper towel to the enameled surface. Do not use paper handkerchiefs as it contains often oil or grease.

7) Allow the water or adhesive to dry well.

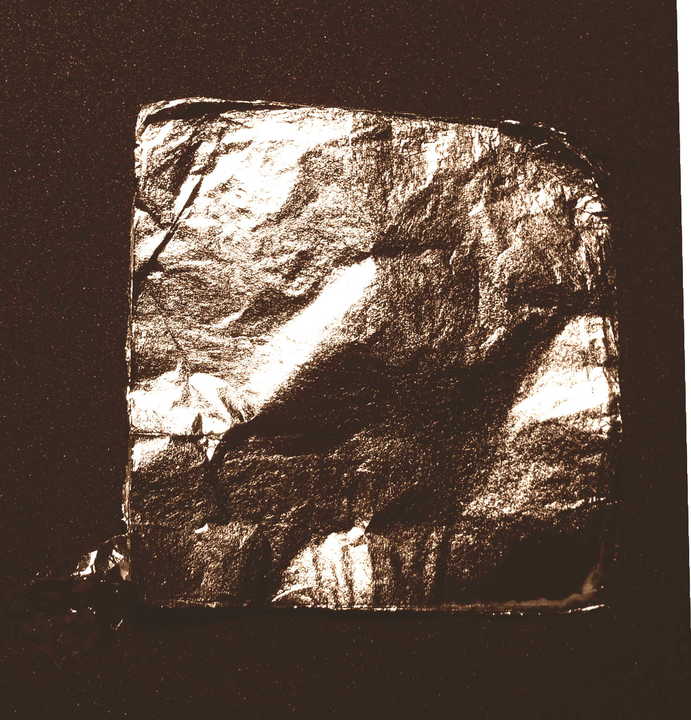

8) Fire the work-piece.

9) After cooling, press the foil again well to the enamel surface. If there are cavities under the foil, the foil can melt in these places during further processing.

Finally, a tip. For example, if you use silk paper in place of writing paper, the creases become finer.

Another way to roughen foil very finely.

1) Place a piece of silver foil on a coarse sheet of sanding paper. Grit at least around 60 or coarser

2) Aplay a piece of semi-hard rubber, for example moss-rubber on the foil and, for example, hit it with a rubber hammer or the like without any force on the rubber surface.

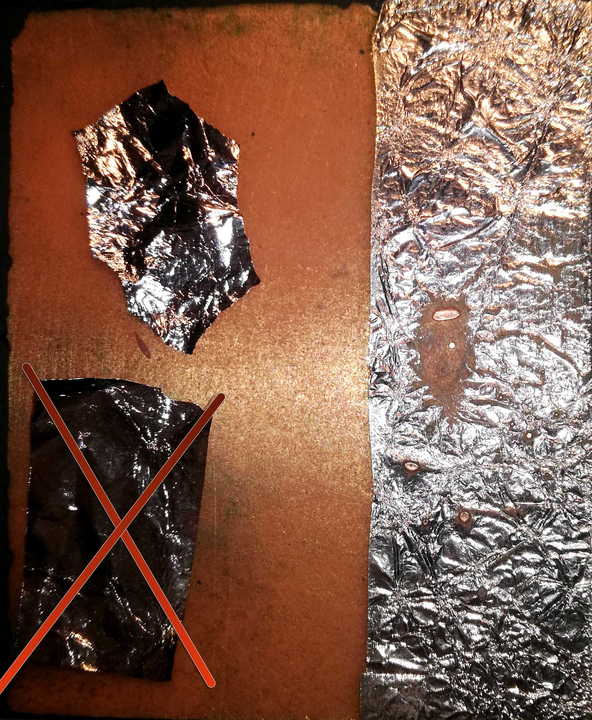

3) Here on the right side of the silver foil you can see the result. A very finely structured surface.

By hammering or press the silver foil to the rough sanding paper surface, the foil gets a little hooked into the abrasive grains. Therefore, it is necessary to remove the silver foil slowly and carefully after the process.

Good luck and fun

Edmund

Hi,

On the basis of a request here a supplement.

If a fault occurs when the silver foil is fired, it can be easily repaired.

Tear a piece of foil so in form, that it is slightly larger than the defect. (Picture 2 at the top left). If the film is cut instead of ripping (figure 2 at the bottom left), the cutting edges may be visible after the fire.

Moisten the defect place with a little adhesive water and glue the torn foil above the defect.

Allow adhesive water to evaporate.

Fire theWorkpiece.

The flaw is virtually invisible after enamelling..

Have fun

Edmund

Edmund you are my master :-) Super repair method.

Thank you

Dear Lescek, thank you for the compliment. In the meantime, you have long since overtaken me. Your cloisonné-style watch-blades are perfect, and in Guilloche-style art is no one better as you. I am proud that I was be free to accompany your first steps.

best regards

Edmund

Edmund Massow said:

Dear Lescek, thank you for the compliment. In the meantime, you have long since overtaken me. Your cloisonné-style watch-blades are perfect, and in Guilloche-style art is no one better as you. I am proud that I was be free to accompany your first steps.

best regards

Edmund

Dear friend - you will always be my master. I don't make cloisonne enamels because I can't afford silver and enamel. Now I engrave more - I like it too. I wish you health my friend.

Dear Lesceck, nice to hear from you again. One don't have also to do everything which are possible. You are a big master in champlevé and guilloche. And only very few people master this techniques!

Best regards in friendship

Edmund