Notifications

Did you make sure you were using a low expansion enamel ? Did you check the Thompson chart under its designated number? You may have chosen an enamel that has a longer softening point and not fired it long enough.

Thank you, I will make sure to check this. Is a low expansion enamel one that fires at a lower firing number?

Mary Rose

Understanding the Thompson charts can be mind boggling - and a very important bit of information that seems not to be touched on in enameling books. When you look at the charts there are 5 columns of numbers - the first column is the number of the Thompson enamel you are selecting - the next column is FUSION FLOW (in lay-mens terms - "how runny the enamel is when firing," i.e. Hard or soft - ) will it melt in under one minute or will it take longer -

The next column is Expansion and the next column is Diatometric Softening Pt. or MELTING point in Centrigrade and Fehrenheit- I was taught to use the second column FUSION FLOW-

The Fusion Flow numbers run from the 20"s up to over 100 - SO THE KEY TO FIGURING THIS SYTEM OUT is to remember and write this on your chart - THE SMALLER THE NUMBER THE LESS RUNNY will the enamel be - making it a more harder enamel - a harder enamel takes a little more time in the kiln to flow.

So when you are layering enamels on a piece - you don't want your first layer to be an enamel that is soft under another top layer enamel that is harder - because your bottom layer will melt quicker then your top and you will have major problems. A soft number can go over a hard . Now with the crackle, you may want to use a soft enamel so that it melts quicker to give you the effect.

I hope this helps.

Thanks Trish, that is a great lesson. I had learned that it should be soft over hard but did not know about the numbers from fusion flow. I agree that i haven't seen this in enameling books. In fact this a.m. i was reading the charts and was very confused. I appreciate your help,

Mary Rose

Has anyone had any experience with Crackle Nos. 1006, 1008, 1997 from Thompson Enamels?

The small workbook says liquid form enamel will produce crackle effects when fired over low expansion enamels such as these above-named items. p. 4

I tried the crackle No. 1008 over and under regular enamel and it does have a little movement of crackle.

Has anyone experienced these?

Mary Rose

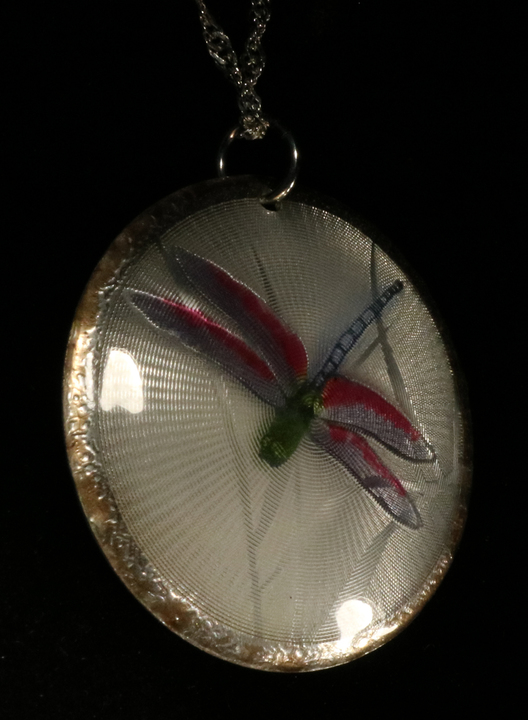

I sometimes use Thompson enamels over Japanese leaded enamels and the crackle. I've starting using this effect purpose in places in my work. You can see it on boarder of this piece. The image doesn't give it justice but it provides an interesting and very cool 3D effect.